Electric Drive System End-of-Line Quality Test - Abnormal Parts

-

Test Object:

NEV Electric Drive Systems -

Application Scenario:

End-of-Line Quality Test -

Challenges:

- The test vehicle was functioning abnormally, which "acceleration beyond a certain speed range would result in a rapidly intensifying noise that tapers off just as rapidly".

- The traditional method of testing at a few fixed RPMs could easily lead to the missed detection of these abnormal parts.

-

Method of Evaluation:

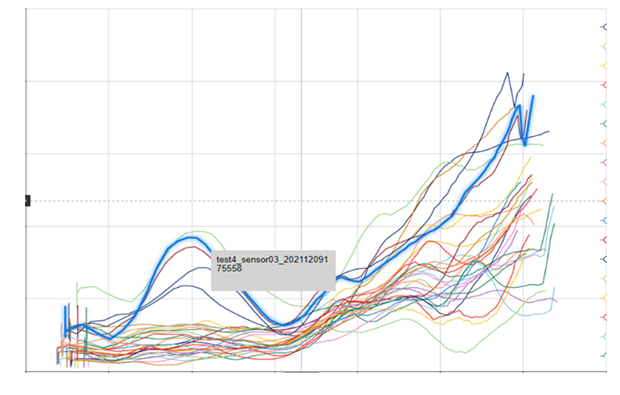

SigMA supports real-time data acquisition and analysis under dynamic conditions (Figure 1). The above abnormal parts can be easily identified using Order Tracking (see order cut in Figure 2).

Figure 1: EOL quality test is being conducted on the electric drive system using SigMA

Figure 2: The different trends of abnormal parts vs normal parts as displayed in the order cut

Related application cases

-

Hybrid Powertrain End-of-Line Quality Test - Gear Nick

-

Electric Drive System End-of-Line Quality Test - Abnormal Parts

-

Electric Motor End-of-Line Quality Test - Abnormal Noise

-

Electric Motor End-of-Line Quality Test - Eccentricity

-

Heavy-Duty Truck Axle End-of-Line Quality Test - Gear Mesh Noise

-

Commercial Vehicle e-Axle Performance and Durability Test - Periodic Noise

-

Vehicle Onboard Health Monitoring - Drive, Brake and Steering Noises

-

Electric Drive System Early Failure Diagnosis - NVH Degradation